High shear homogenzier is developed and manufactured by us based on world-class advanced technology, the quality strictly comply with GMP and ISO9001, especially apply to food, beverage, chemicals, petrochemicals, pigment, dyestuff, paint and pharmacy industries, the structure is compact, simple operation, lower noise and stable running, and there is no media during whole process to realize high shear, dispersing, homogenizing, mixing and transferring.

HIJ (vertical) high shear homogenizer make one or more phases into one continuous phase, and normally every phase is not melted with the other, but the high tangent speed and high frequency mechanical effect of rotor make the solid phase, liquid phase and gaseous phase equally homogenized in very short time with corresponding technology and additives, finally get the stable and high quality products.

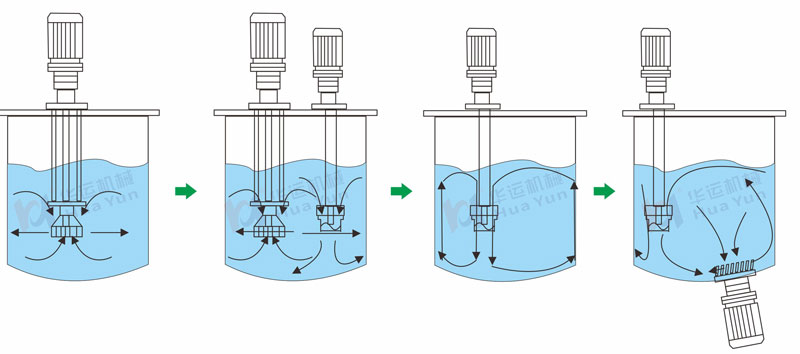

1:The material is sucked into the working chamber from two direction axially due to the centrifugal force generated by rotor

2:The material is squeezed and crashed while it is tossed to the space between rotor and stator by centrifugal force, this process called”elementary homogenizing”.

3:The tangent speed of rotor can be adjusted maximally to 40m/s, and generates mechanical and hydraulic shear, friction, crash, this get the material dispersed, homogenized and crashed completely and shot out through stator at the same time.

4:The material is continually shot out radially, and its flow direction changed due to the resistance of container wall and itself, meanwhile the flow generated by axial suction of rotor also exist, over and over again the material get dispersed and homogenized.

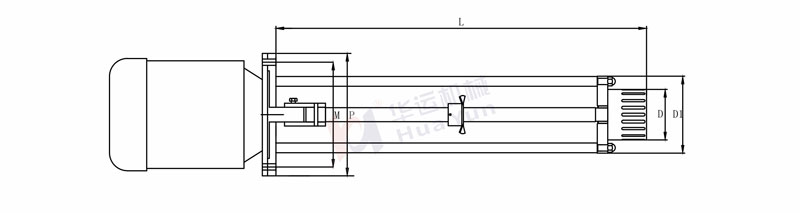

Model |

Power (Kw) |

Rotary speed(rpm) |

handling capacity (L) |

D |

D1 |

P |

L |

M |

|||||||||

HIJ101 |

1.5 |

2800-2900 |

5-50 |

80 |

140 |

200 |

355 |

165 |

|||||||||

HIJ101 |

2.2 |

2800-2900 |

50-100 |

88 |

145 |

200 |

650 |

165 |

|||||||||

HIJ105 |

4 |

2800-2900 |

100-300 |

120 |

180 |

250 |

750 |

215 |

|||||||||

HIJ110 |

7.5 |

2800-2900 |

200-800 |

140 |

210 |

300 |

900 |

265 |

|||||||||

HIJ115 |

11/15 |

2800-2900 |

300-1000 |

160 |

230 |

350 |

1050 |

300 |

|||||||||

HIJ120 |

18.5 |

2800-2900 |

500-1500 |

180 |

260 |

350 |

1200 |

300 |

|||||||||

HIJ125 |

22 |

1400-1500 |

800-2000 |

200 |

270 |

350 |

1200 |

300 |

|||||||||

HIJ130 |

30 |

1400-1500 |

1000-3000 |

240 |

320 |

400 |

1355 |

350 |

|||||||||

HIJ150 |

37 |

1400-1500 |

1500-5000 |

260 |

340 |

400 |

1395 |

350 |

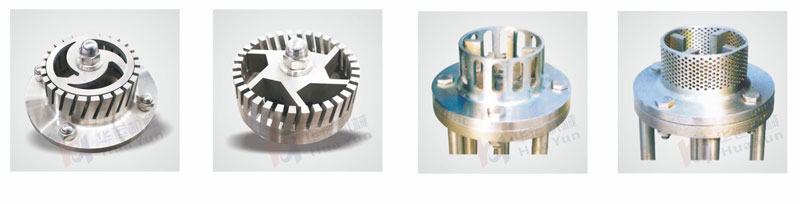

(images from left to right)

E-mail:huayuncompany@126.com

Factory address:No.25, Jinhai Road, Shuangfeng

Economic& Development district,Hefei, Anhui,CN

Marketing&Sales office:Floor 13th , Meidi

Yangguang mansion,Jinzhai road, Hefei City.

Copyright 2018 Hefei Huayun Machinery

Manufacturing Co., Ltd

*Part of the webpage materials and related resources on this site are from the Internet.

If there is any infringement, please inform us immediately and we will delete it within 24 hours*