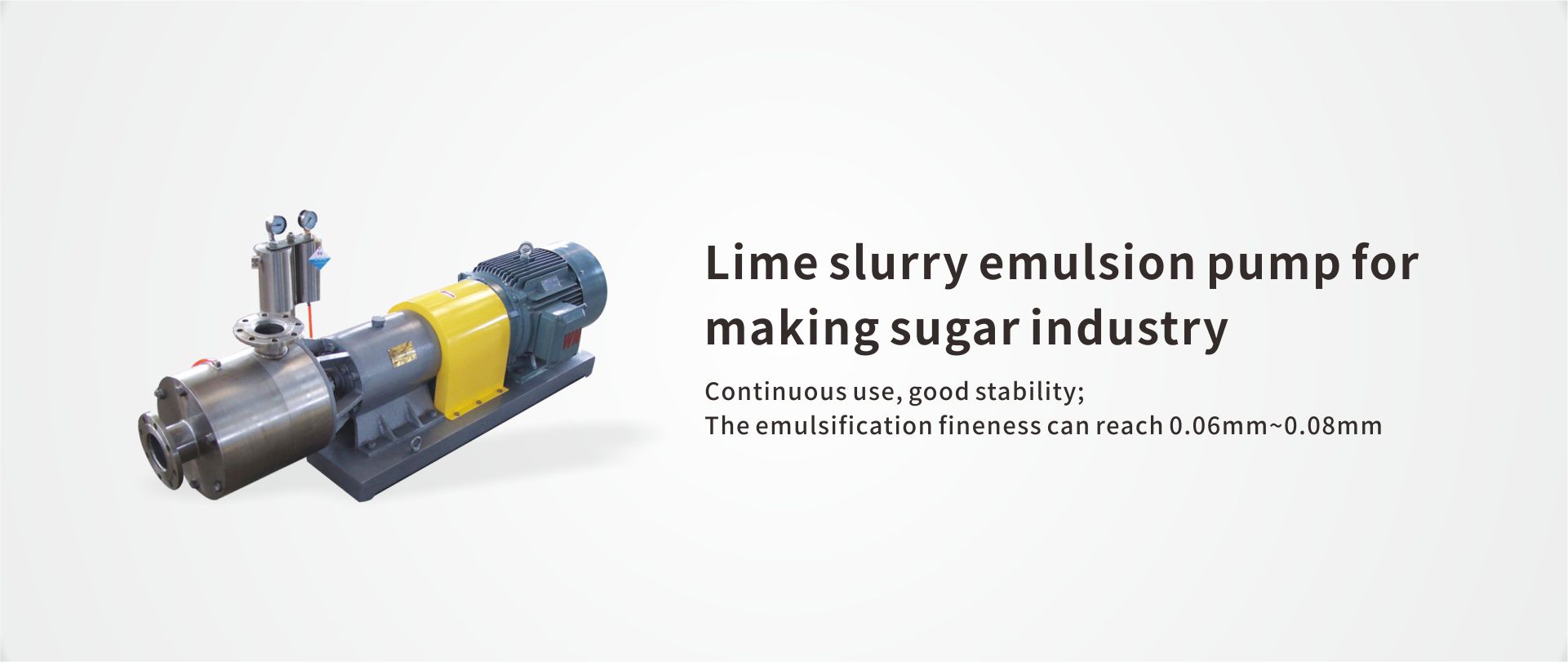

Hefei Huayun Machinery Manufacturing Co., Ltd. production of special lime slurry emulsion pump for making sugar industry is a set of transport and high shear emulsification as one of the special pump, the application of special lime slurry emulsion pump, to overcome the sugar factory for many years because the lime slurry is difficult to refine, resulting in post-reaction, resulting in sugarcane juice neutralization and clarification juice PH value is difficult to control, ultimately affecting the quality of products.

According to the general process of the sugar factory, the preparation of lime slurry is made by using the lime dehydrating machine to heat the lime into the lime slurry in the cylinder of the dehydrating machine, and the lime slurry flow trough flows into several lime slurry storage barrels with agitators (mainly for precipitation and sand removal). Then use ordinary lime slurry pump (generally using centrifugal pump, mud pump and plunger pump) to transport sugar cane juice for pre-ash and post use, such lime slurry particles are usually about 1~3mm, and contain more fine sand, which brings a lot of problems to the following process:

First, most sugar mills are equipped with pre-ash PH, neutral PH and clear juice PH automatic control equipment, they are characterized by high prices, stable control, but they also have high requirements for the quality of lime slurry. As the above large particles, sand containing a lot of lime slurry will block the lime slurry pipe and damage the main components of the automatic control equipment, resulting in automatic control failure.

Second, the reaction after the large particles of lime slurry is serious, resulting in the neutralization PH value and the PH value of the clear juice is difficult to control and stability, and ultimately affect the quality of the product.

Third, the lime slurry with large particles and much sand brings serious scaling to the equipment in the clarifying and boiling section, affecting the heat transfer, increasing the steam consumption and the cost of washing the tank, and some scaling is brought into the sugar products, leading to excessive amounts of insoluble magazines.

It can be seen that the centrifugal pump, mud pump, plunger pump is only a simple transport pump, they can not change the size of the milk of lime particles, can not solve the above problems. If the use of Hefei Huayun newly developed, with a number of national patents of lime slurry pump (lift up to 30M), it can not only complete the transport of lime milk, but also in the transport process of 1~3mm of lime milk particles shear into 0.06~0.08mm of lime milk, directly used for cane juice pre-ash and neutralization, better solve the above problems. It provides a guarantee for the stable control of PH value of pre-ash, neutralization and clarification, and ensures the stability and improvement of sugar quality.

In the application of some sugar mills in Guangxi, Yunnan, Hainan, Guangdong, Fujian and Inner Mongolia, the special pump for lime slurry not only improves the emulsification efficiency of lime slurry, but also greatly improves the quality of lime milk, thus making the quality of sugar more stable. This pump is a revolution of lime emulsification in the sugar industry, it is not the same concept as the ordinary lime milk pump (centrifugal pump, mud pump, plunger pump), it is a pump that can bring high efficiency and high quality to the key process of lime slurry emulsification in the sugar industry. Nowadays, many sugar factories generally use high precision equipment such as pre-ash, neutralization and PH automatic control of clear juice, and the quality requirements of sugar products at home and abroad are getting higher and higher, and the quality requirements of lime milk are getting higher and higher. Therefore, the use of lime slurry pump produced by the company to replace the ordinary lime milk pump is a good choice for sugar enterprises.

English

English Chinese

Chinese